So... the rest of the story...

Let's start with a few pics... the sad sight I was shocked to see:

Figured I let the chain get so loose it was throwing and rubbing on the Sandman case protector...

So I parked the bike, kicked my ass a whole bunch for being so incredibly negligent I didn't notice that happening while doing regular chain maintenance, posted about it here, etc. Couldn't believe how I had been such a moron to allow that to happen - especially after I thought I was being wary of that after seeing it happen to others. But didn't understand either, as I run my chain a bit on the loose side of the adjustment range and check it regularly while doing chain lube chores. This is supposed to be caused by tight chains. Or 12 tooth sprockets if you prefer that reason. Neither of which applies to me.

Turns out nobody seems to keep these "seal protectors" in stock. Eventually, my fast-as-possible delivery "seal protector" arrived via 2nd Day air once the seller got it from Yamaha - just one, because after I got it fixed I was going to see if somebody would soon make a better aftermarket one.

Had to go to town to make an appointment with the lawyer the same day the replacement slider arrived. So I left off replacing the sprockies and chain - because they still looked more than acceptable and the chain didn't seem to have any tight or loose spots - for the next day. With a properly adjusted chain, and a new chain slider, how bad could 20 miles be?

Well, as it turned out, this bad:

After my wife told me to quit screaming and brought a crowbar out and pried me off the roof of the garage, I checked the chain tension: 8mm spacing while on the sidestand, perfect Yamaha adjustment. WTF, over?

Screw waiting for my brother to show up, I started tearing my wounded little bike apart to try and figure out what the hell was going on. Tore swingarm, linkies, shock, Yamalink etc off to check for seized bearings or collars or something. Didn't know exactly what I was looking for, as a mechanic I ain't. But I'm a jackleg machinest and I figured something had to be seized or bent or something. Everything moving and lubed. Even started measuring stuff up with micrometers and dial indicators, trying to find something that wasn't right. Didn't have the courage to throw calipers in the worn slot to see how much material was left... I figured this would be one of those cases where ignorance is bliss.

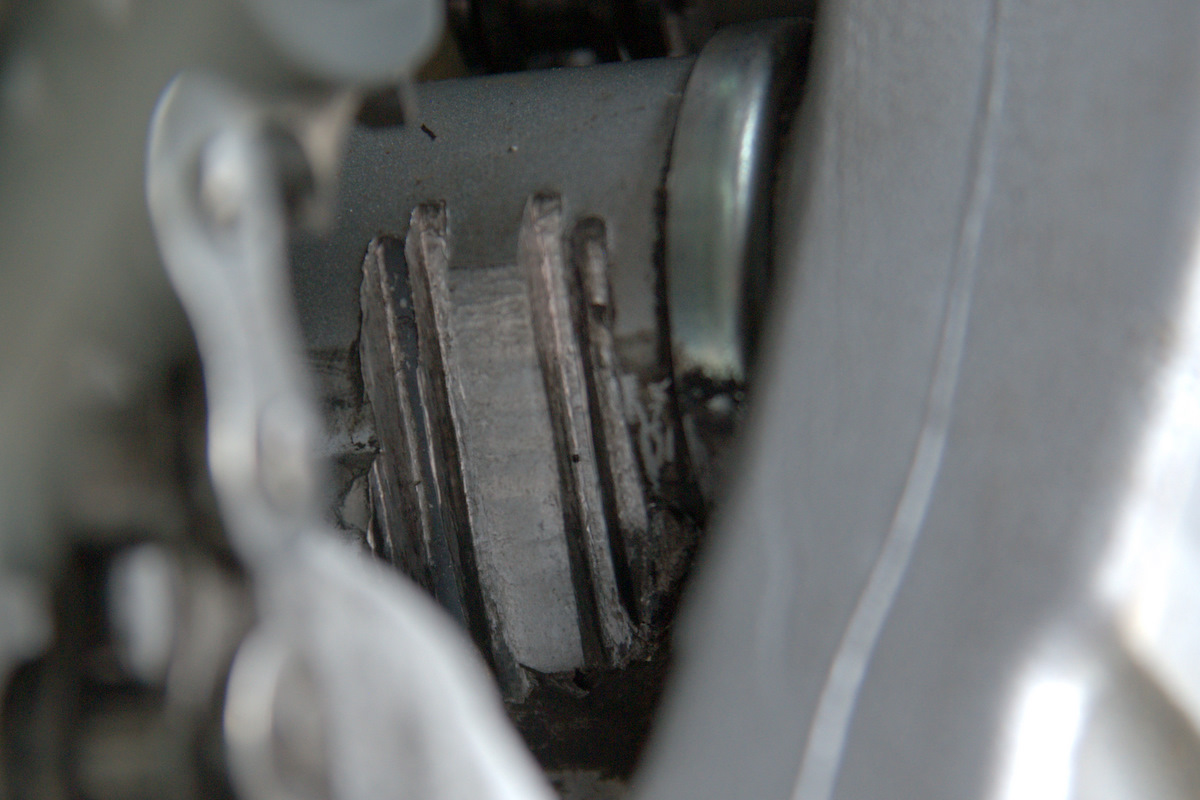

No luck with any of that, but it did allow a closer view of the damage:

Couldn't find anything wrong. I was goin' crazy here. Until I decided to check and see if I should be ordering a new rubber insert for the rear chain guide while I was ordering a couple of dozen chain sliders. And then I saw what at first seemed like a rubber part had peeled up and come adrift.

And then I suddenly realized what I was looking at:

A damned rock! Well worn in by now.

Talk about The Golden BB taking you out. What are the chances of a rock coming up off the front tire, and being perfectly aligned with the opening of the chain guide when it hit it. And not only being perfectly aligned and arriving at an instant when the chain was high enough in the guide to let it enter, but being big enough to stick and not small enough that the chain simply pulled it out the back?

To make The Golden BB effect even better, it wasn't just any kind of rock. No, it couldn't be one of the softer sedimentary rocks around that would have been quickly fractured or ground down. See that kind of waxy look? That rock is chert. For those who have never worked underground in a hard rock mine, chert is the kind of rock that makes drillers cry when they find their worksite is in chert; they drop their lunch pails so they can carry an extra bag of drill bits. It ain't as hard as steel, but hard enough - another name for chert is "flint".

Yes, what are the odds? The perfect Golden BB.

So I threw the new sprockets and chain I had on hand (14/49, 112 link chain). Once I get over being pissed off, maybe I'll go examine the old chain to see just how badly it is worn, measure the gullet on the sprockies, etc. Or maybe not...

So now the cause of what happened is solved, patch the swingarm. Toyed briefly with getting a skilled welder to fill it in, then thought of what doing that would entail, possibility of things going bad, etc. Decided to skip that idea. Filed out the damaged area and fitted a small piece of round stock that would fit in the resulting notch to provide a hard point to stop further chain wear on the swingarm should this ever happen again. Hardened it up and then fitted it in and filled the notch with JB Weld.

I had intended to take a Dremel and shape the repair to match the curve of the swingarm. Then I noticed it was close already (didn't want to shape more of the hardened JB Weld than I had to) and didn't interfere with where the swingarm slider sat, even when it was a little bit proud. So I left it and called it good.

Now I had a fixed bike (I hoped... by this point I was pretty gun shy). But while I had ordered two more swingarm sliders, they wouldn't get here for a week and I was back on foot and mountain bike again. So I decided to try my luck and see what would happen: repair the damaged "new" slider. Grabbed some Tech Plastic, a plastic/fiberglass stick I use in gunsmithing that you activate by kneading the two component parts together. I thought about JB Weld briefly, but wondered if it would be too hard or inflexible when the slider flexes, etc. So the finished repair to the slider looked like this:

I left it a little bit proud when moulding it into what remained of the front of the slider, held together by a last few bits and pieces. Thought about dressing it down to the original contours, but then decided to let the chain do that and use the wear as a bit of an indicator on what kind of contact I was getting.

So, bike back together, swingarm and pivot rod and linkage bits and pieces all cleaned up with mineral spirits and regreased with Belray Waterproof grease. Used up the inch of lowering in the rear shock while I was at it, something I've been meaning to do. I am such a shortass, my legs barely reach my feet.

Sidebar Note: HighFive isn't kidding when he says that plastic matrix the needle bearings sit in is fragile - I tore some bits and pieces out just rubbing them back and forth with a gloved finger while cleaning with mineral spirits. Not picking at them with a fingernail like HighFive did. Wife had to come out and pry me off the garage ceiling with the crowbar once again, etc. I mean, they damage REAL EASY - almost effortlessly. Nothing about that in the Service Manual...

Like HighFive, I put the bits back as best I could and hope the grease, the remaining matrix around the damaged parts, and the fit will keep all them needles where they're supposed to be. If not....

Loaded some tools up and headed out to hit some potholes and washboard to see if there would be any more instantaneous damage to the slider. But, bigger sprockies... chain tension first... hmmm.... I'm in a hurry. Yamaha says 8 - 13mm distance between chain and swingarm on sidestand. I decided to use 6mm distance between chain and swingarm with minimal pressure. With bigger sprockies and lighter pressure, closer than at the loose end of the stock adjustment range, that should be a safe chain slack setting for now. Will explore that with Sarah at a later date as I think her drive and suspension setup is pretty comparable to mine.

Link to that day trip is

here.

Anyways... the good news is that everything now works as expected. Stopped to check after 5 miles, 15 miles, and 30 miles. Just a bare amount of wear on the proud parts of the repair to the slider. 300 miles later, the wear doesn't feel any different. I suspect I could use this repaired slider for thousands more miles (but I'll swap it out once my new sliders get in and keep it for a spare and a memory).

Other notes related to the repair (aside from confirming HighFive's warning).

First, I really, really like the 14/49 setup. Might be my imagination, but the drive feels a bit smoother than the stock 13/43 I've used to date. It definitely ISN'T more vibey. And the power is much more usable over the entire transmission range. I don't notice much difference in 1st as little of my riding makes use of first gear grunt. But where before I found 6th (and often 5th) useful only for low rev slab motoring with insufficient power to even pull a hill or make a smooth pass, now I find them much stronger and more useful on the highway. For true 50/50 dual sporting, I think 14/49 is pretty close to perfection. Maybe 14/48 - if I could discern a difference.

Second, mileage. Just before I put the bike away last year, I posted

Hey! Where did my mileage go?. Well, it didn't come back this spring despite all the theories, and I hadn't had the time to try sorting it out after trying the usual suspects. With the rock out of the chain guide, my 50/50 dual sport ride up Redding Creek netted me 85mpg Imperial/71mpg US. Which took care of that question. How much had to do with the rock and how much with the worn (but NOT worn out) sprockies and chain? Hard to say. On the one hand, given how fast my new chain slider got eaten, I would think I got lucky because I caught it before it ate right through the swingarm in a number of days. On the other hand, perhaps the majority of the wear happened immediately when that rock was biggest, and then decreased as the rock got worn down by the chain. Until it wore on the chain enough that it went suddenly, significantly, slack.

But, in either case, my mileage is back as well. I did a steady 60mph run until the fuel light came on, ended up refueling at exactly 100 miles. Worked out to 66mpg Imperial/55mpg US. So losing the low rev, low grunt 6th gear will cost me a bit in high speed slab riding, but those higher gears are also more useful on the highway and for dual sport riding the entire gear box is much more useful.

Total cost of this little adventure: about $200 and three weeks of mostly being afoot so far. And a damaged swingarm that I really, really hope won't end up needing to be replaced.

Pan to Paul Harvey...

And now you know... the rest of the story.Won't help to identify the root factors in why some swingarms get eaten and some don't, however.

One..... Freaking... Rock. The Golden BB.